Wet paint spray technology

Pre-treatment

Pre-treatment and its appropriately chosen method are the main prerequisites for achieving the desired corrosion resistance of the coating. Variables such as the nature of the contamination and its intensity determine the choice of the appropriate treatment method. In general, for paint application, the workpiece surface must be free of all grease and the surface must be dry. Different compositions of chemical pre-treatment or blasting stages are used to meet this requirement, depending on the material being treated and the corrosion resistance of the paint.

For chemical surface preparation - deoxidation, degreasing, phosphating and following rinses, demi water rinses and passivation, we provide continuous spraying equipment and immersion or manual spraying chambers. Circulator pumps for demi water production is also included. Pre-treatment technology also includes wastewater treatment plants for environmentally friendly disposal of rinse water. The equipment can either be integrated as part of the line or supplied separately.

Waste waster treatment

When considering the design of the surface treatment plant, it is also important to take into account the consequential disposal of waste water (especially from the chemical pre-treatment of the raw product). With respect to this vital aspect, we are ready to provide you with waste water disposal equipment as part of the package of the entire plant or separately to the existing plant. Waste water treatment plants are always designed in relation to the given type of plant and can be supplied in various configurations, from manual to fully automatic. The waste water treatment and disposal process is always adapted to the required parameters and local discharge limits set by the local authorities at the installation site.

The treatment plants can include additional accessories such as sand filtration, activated charcoal, or multi-stage pH measurement with fully automatic dosing of chemicals needed in the process of neutralization. The entire process of waste water neutralisation is recorded within the control system of the plant.

The waste water facility will significantly reduce the operating costs of external waste water disposal.

Paint and dry booths

Industrial painting and drying booths are most frequently used for surface finishing of steel structures, weldments, castings, cars, aircraft or rail vehicles.

These booths always include exhaust air units and air handling units for supplying clean air to the booth containing an appropriate filtration to achieve the desired coating quality. With regard to the environmental impact of the paint booth, a volatile organic compound (VOC) calculation is always performed to design a corresponding filter system or disposal system.

If required, it is also possible to equip the painting facilities with handling equipment for operators - sliding platforms with controlled travel in all axes, pneumatic mobile platforms or overhead cranes or overhead conveyors for handling products.

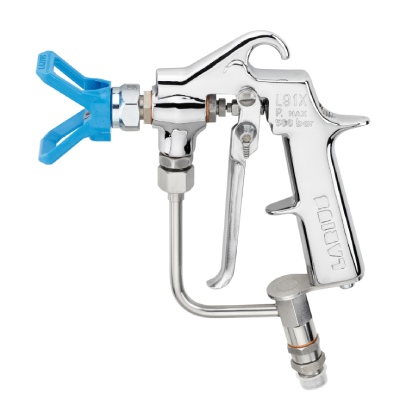

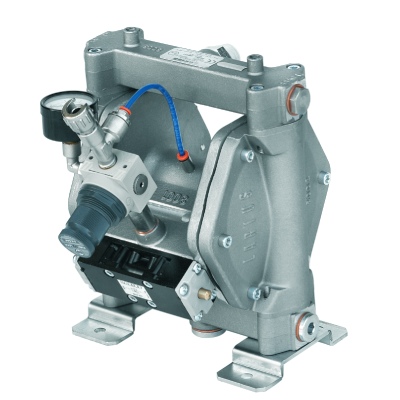

Paint spray equipment

As part of our product portfolio, our offer includes a wide range of equipment for wet painting applications, including pumps, paint guns and additional accessories.

This wide product range includes dozens of pump types with different gear ratios and different volumetric delivery, which is the determining factor for the selection of equipment with respect to performance. The pumps are designed for the application of solvent-based and water-based paints, low and high viscosity materials. We feature a wide range of accessories for the application equipment, which allows for spraying all types of surfaces.

When designing the application equipment, we always focus on the type of production and all your requirements. We then design the most ideal solution.

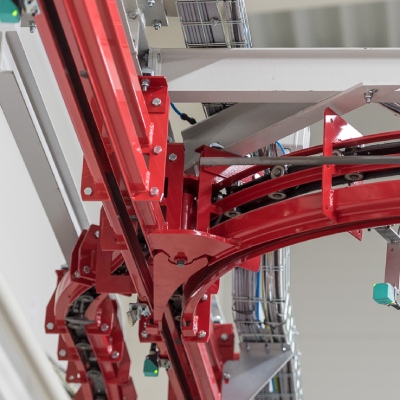

Conveyor systems

To move products between individual facility units, the option of a manual or automatic conveyor is available for surface treatment. Manual transfer can be carried out using push carts, roller conveyors or overhead conveyors. The automatic conveyor uses a single track or a double track system, i.e. Power & Free.

Power & Free conveyors allows to release or stop individual trolleys at any given time and to disengage or accumulate trolleys at various points within the conveyor system.

To handle heavy products, the conveyor system is fitted with a loading and an unloading station.

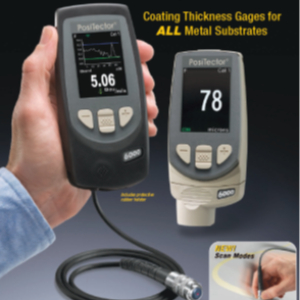

Accessories

In addition to painting equipment, we also offer a wide range of accessories and various types of inspection instruments.

All our range of accessories can be found in our e-shop.