Abrasive blasting

Blasting is a mechanical surface pretreatment that can be performed manually or automatically.

Manual blasting is accomplished in blast cabinets using mobile or stationary blast equipment. Blast pots with a capacity of 20-300 l allow the use of different types of abrasives. The recovery of abrasive media from the blast cabinet can also be manual or can be done automatically by means of a conveyor with return of the abrasive media to the blast equipment. For light types of abrasives, so-called M-section (vacuum blast material collection) can be used.

Automatic blasting systems use either overhead conveyors or continuous flow type. The abrasive medium is blasted onto the part by means of blast wheels, where it is then conveyed to the elevator, separated from impurities and returned to the hopper.

Blast machines by Clemco

SURFIN Technology is the chief dealer of Clemco's mobile blast machines and booths.

We are able to deliver surface treatment facilities with closed circulation, filtration, recycling of abrasive media, and equipment for pipe blasting. Supply of spare parts and protective clothing is also an integral part of our wide portfolio of products. Clemco products have been proving its quality over a long period of time. Our long-time cooperation with Clemco is why we are able to offer expert advice and maintenance in industrial pre-treatment.

Blast chambers

Blast chhambers are suitable for cleaning and pre-treatment of the surface of weldments and steel structures. The facility is equipped with a full reverse floor abrasive media conveyor, elevator and abrasive media separator and air blast units with protective gear for the blast operators by default. The chamber has a service door, lighting and abrasion resistant lining to the walls, ceiling and door. Manual loading on a trolley or on a track with one or two doors. The technology can be used for blasting steel, non-ferrous metals, stainless steel, aluminum, or cast iron.

Automated blast units

Automatic blasting can be performed either in a closed enclosure, i.e. in a blast one-way chamber, or in continuous flow chamber. The abrasive medium is wheel blasted onto the workpiece, after which it is conveyed to the elevator, separated from impurities and returned to the hopper.

Blast chamber with overhead conveyors is suitable for blasting medium sized items. The workpiece is brought into the chamber where it is automatically wheel blasted. During the process, the blasted product rotates. When the blasting time is over, the part is taken back out.

The workpieces can enter the continuous flow blast chamber on an overhead or roller conveyor. During the blasting process, the blast wheels are static and the part is moved along on the conveyor. Continuous blast units consist of an infeed chamber, a main blast chamber and an outfeed chamber with automatic blow-off facility to romve residual abrasive material from the product. At the outlet, it is as well possible to have a manual finish blasting unit and a air blow gun.

Large automated blasting hubs are capable to treat all types of railcars, longitudinal frames and any individual parts of the workpiece, without the need for staff intervention. The chambers can be made up to 30 m in length, 6 m in width and 6 m in height. Blasting is carried out with eight blast wheels on oscillating bases and two blast wheels on the roof of the chamber. The movement of the parts is ensured by a motorised chain conveyor. The blasting machine consists of an inlet, a main blasting chamber and an outlet chamber. The blasting intensity can be controlled by frequency changers.

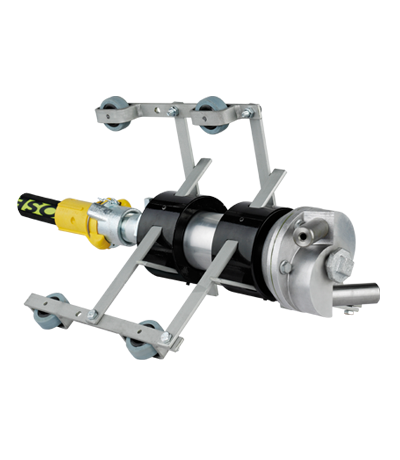

Accessories

We also provide a wide range of accessories for blasting equipment, such as protective gear, hoses, nozzles and blast lamps.

All product extras can be found in our e-shop.