Robot-assisted coating

Robotic powder coating

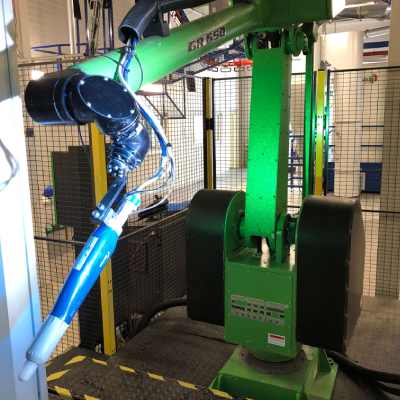

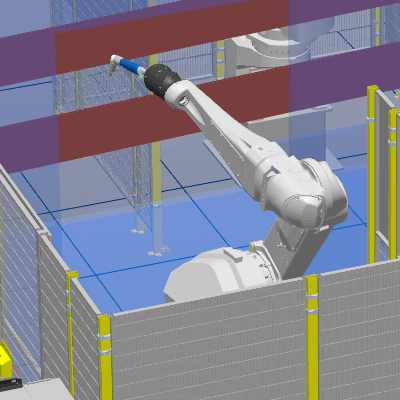

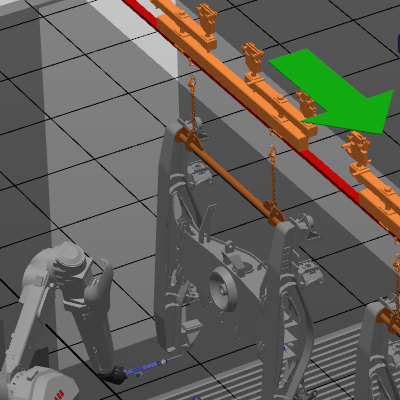

To ensure high quality powder coating, it is important to comply with many parameters of the technology, such as the stability and repeatability of the process of applying powder paint to the product. The best way to achieve this is to incorporate robotics into the workplace. ATEX-certified industrial paint robots combined with innovative application technology are the best choice. The robotic workplace is always customized according to the requirements of the manufacturer and the type of production.

One of the many examples is integrating a self-learning robots that are programmed by the operator using manual guidance. Another way of programming is with offline tools in which robot programs can be created without having to stop production. These offline tools also support virtual reality. Another indisputable advantage is the increase in the speed of the entire powder coating process.

Robotic spray painting

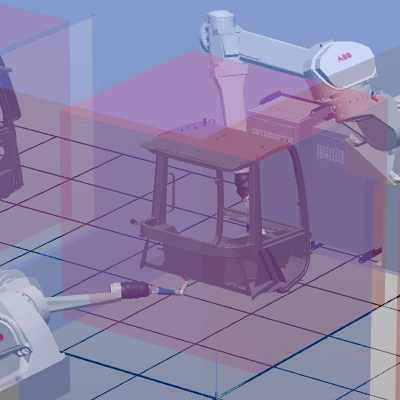

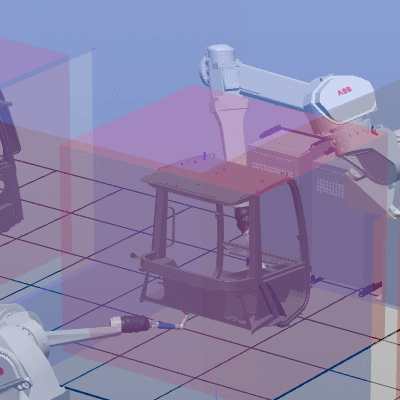

By robotizing the paint application process, we not only achieve higher efficiency and increased production capacity, but we also have complete control over the entire painting process and the setting of painting parameters. The application technology is controlled directly from the robot system and allows to change the parameters continuously during the course of the robot's trajectory. This feature ensures excellent quality of the final coating even with very diverse products. The robots come in a variety of configurations, together with the application technology and paint management. If desired, they can be fitted with CCV valves for fast colour changes; the hoses with the desired colour shade, etc. The operation speed is in the order of 10s of seconds. We always approach each project individually and develop solutions to meet your requirements, considering both the technical solution and the financial return.

Robotic spray booths

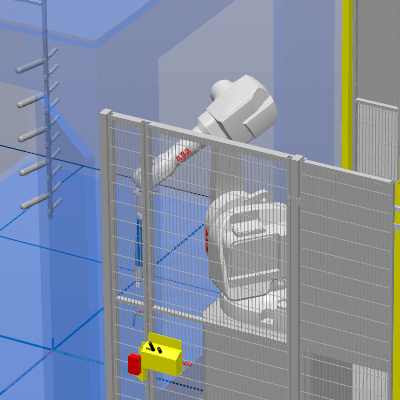

Besides maximizing its effectiveness, the utmost importance is put on the safety of the workplace. Robotic paint booths are always equipped with the necessary safety features (e.g. safety sensors, fire extinguishing system, etc.). The design of the robotic paint booths and the materials used always vary depending on the application technology and the production system used. Robotic powder coating booths may include systems for powder paint recycling and reuse or systems for rapid color change. Spray paint booths for wet paint application may also include a water wall, various types of filters, an air recovery and air exchange system in the paint booth with humidity control, or a system for the disposal of VOCs. The facility is designed in line with applicable regulations.

Paint distribution system

Our solutions can also include wet paint distribution systems (colour management). These systems are always designed based on the specific application and the type of paint used. They can be designed for 1K application, or 2K application of solvent and water-based paints. Both the application area and the setting of a given system are determined by the required performance, the number of shades and the changeover period. These systems can also provide consumption reports and maintain a constant ratio and viscosity of paint.

Effective control of the paint distribution process and monitoring of all available parameters is essential for the final quality of the finish.

Powder paint distribution systems

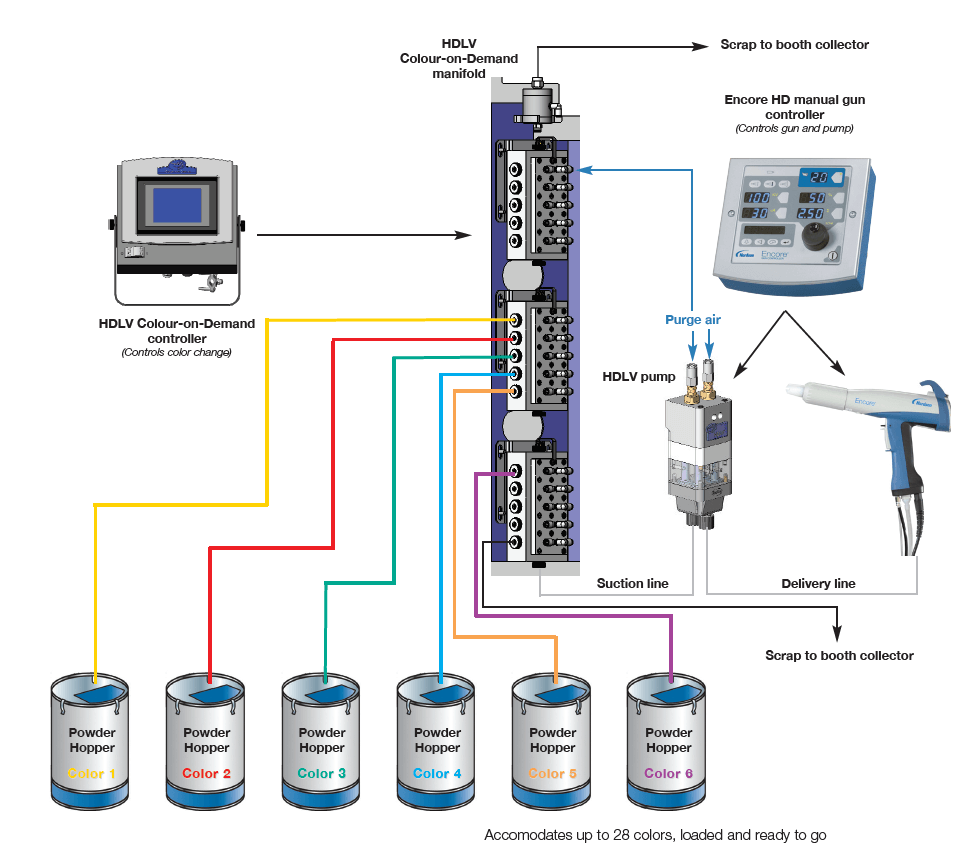

Encore HD Color-on-Demand

The Encore HD Color-on-Demand system with HDLV (high-density power, low-volume air) is a patented technology by Nordson Corporation for instant color changes within a given time period. This technology improves the speed of the application process and significantly increases the coating plant's production.

Combined with the Encore HD automatic gun system, it provides an integrated solution for precise dosing and ultra-fast contamination-free colour change.

The system features a colour touch screen with user-configurable buttons.

Up to 28 hoppers with different powder paint shades can be connected to the feeding system.

Key Features of Encore HD Color-on-Demand:

- less than 20-second color change;

- full-color touch screen display;

- user-configurable buttons;

- accomodates up to 28 hoppers of paint;

- automatic purge cycle;

- no manual changing of colors required

Encore HD Color-on-Demand system Diagram:

Esco control system

Application tools and accessories

Quick tool-change system for powder paint application

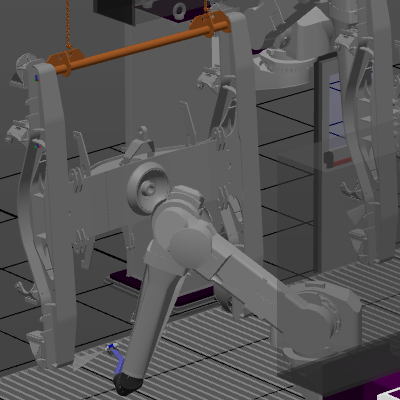

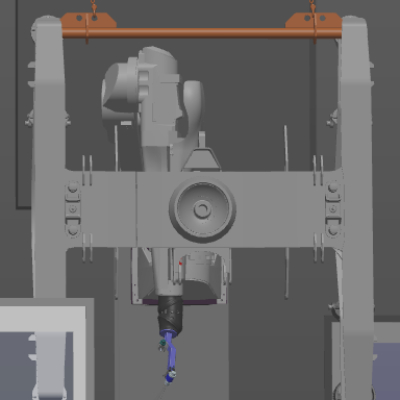

POWDER TOOLCHANGER

Toolchanger is a unique system for quick tool change that is carried by the robotic arm. This system is fully certified for use in explosive atmospheres (ATEX) and is ideal for manufactures with very different product types where multiple tools (paint guns) have to be used to ensure the efficiency of the painting process. This tool can be equipped with different types and versions of application equipment and tools for automatic cleaning of the paint booth. In the painting process, the robot selects the optimal tool according to the parameters of the product. The variability, efficiency and working range of the robotic application is significantly higher when using this system than with the standard use of only one working tool. The result is a considerable reduction in costs and the consistency of the painting process.

Automatická pistole ENCORE® HD

Robotická lakovací pistole s HDLV technologií distribuce barvy

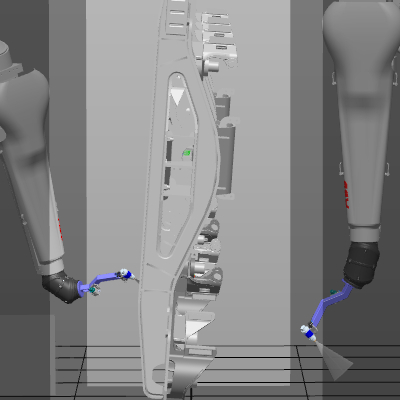

ENCORE® HD ROBOTIC POWDER COATING SPRAY GUN

- the fourth generation of Nordson spray gun with HDLV technology

- Integral-power-supply to deliver optimal voltage at 100 kV to ensure the best performance of the powder apllication

- feeding system to transport dense powder amount mixed with air at low speed (HDLV) for optimal powder output and coat thickness

- designed for powder coating of complex geometric product shapes

- delivers consistent, repeatable performace of powder application

- fast colour change gun without the need to dismantle the guns

- highly durable material to minimize wear

- aerodynamic shape of the gun allows for quick external cleaning of its body to avoid contamination at each color change

- large selection of nozzles

HDLV® GUN PUMP

- ensures precise and stable powder paint volume distribution to the spray guns

- dense volume of powder paint mixed with air dispersed at low speed enhances efficiency of powder application

- quick bulit-in pulse-purge function to clean the distribution system within 30 seconds without the need to disassamble any part of the device

- wear-resistant components unlike Venturi nozzle

- linear powder flow for precise powder output

- low consumption of compressed air

- maintenance-friendly

- maintenance interval in the range of thousand working hours