control system

control system

Esco introduces a state-of-the-art comprehensive software solution for Industry 4.0, enabling you to achieve maximum efficiency and productivity of your coating lines. Esco helps you simplify and optimize your work with industrial automation systems. We are constantly developing and upgrading it based on the latest knowledge.

Benefits of ![]() for coating lines:

for coating lines:

- Comprehensive process control

- Immediate visualisation of important processes

- Increased quality and productivity of production processes

- Industrial data management

- Modern graphical interface

- Secure access from anywhere

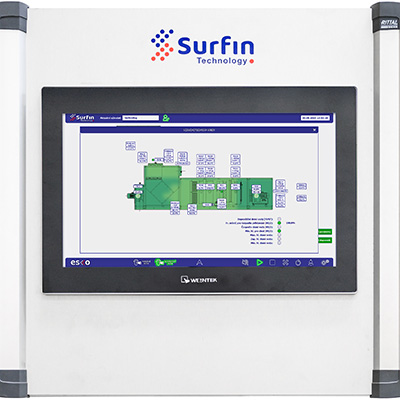

Advanced control system for efficient management and control of coating lines. The ESCO PLC provides centralized control of all processes, safety measures and intuitive operation via a main touch panel.

Features:

- Complete line control system allowing management and control of all processes

- Line control via main touch panel for easy operation and overview

- Autostart - automatic start-up of the line according to set time and date

- Integration of all line technologies in one place for efficient control

- Communication with all peripherals on the line

- Security management of the coating line (PROFISAFE)

- Generation of graphs from analogue sensors - e.g. monitoring of temperature, pressure or flow rate

- History of fault conditions

- Distribution of user rights – roles for administrator, technologist and operator

- Control of pre-treatment, draining and overflow of baths as well as all motorized elements of the line

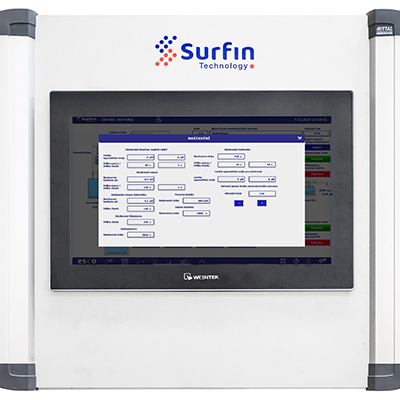

Integration platform for data management and coating line control. ESCO Link enables seamless database connectivity with the production line, ensuring efficient order upload and real-time monitoring of production processes.

Features:

-

Database integration (MySQL) for uploading orders and product information to the virtual conveyor,

which controls the downstream process of the line -

Database feedback - storing information on failure conditions, production times,

number of units produced or loaded - Loading panels enable upload of products to a virtual conveyor for efficient material flow management

- Integration with your ERP system such as ABRA, K2, KARAT or Vision

- Periodic saving of sensor data from the line (Dataline)

- Production history creation (TravHistory)

An intelligent system for integration and control of robotic workstations in coating lines. ESCO Robotic enables efficient and safe robot operation, process automation, and offers the flexibility to create custom programs using advanced tools.

Features:

- Integration of robots into the coating line to optimize production processes

- Sending parameters and programs directly to the robots based on ESCO Link information for each individual part

- Ensuring safety in the robotic coating environment

- Tracking individual products in the queue

- Automated colour changeover for greater efficiency and minimised downtime

- Enabling operators to create their own programs using Robot Studio (for ABB robots) with virtual reality (VR) capability

Professional air handling technology for efficient control and regulation of air flows in coating lines. ESCO Air is designed to guarantee stable and optimal conditions through advanced control processes.

Features:

- Advanced air handling technology for optimizing industrial spaces

- PID control of air flows to booths and other areas of the production line

- PID control of temperature and humidity in the coating booth to ensure consistent quality

- Graphical visualization on touch panel for easy control of parameters

-

System is divided into several independent parts, which allows separate control for different areas

(main area, drying oven, firing oven, cleanroom, etc.)

Advanced technology for automated waste water treatment aimed at improving the quality and recycling of water in production processes. ESCO Aqua provides an environmentally friendly solution for efficient use of water resources.

Features:

- Waste water treatment technology for industrial applications

- Automated filtration and decontamination of waste water

- Water recycling to reduce consumption of natural resources and optimize operating costs

- Water quality monitoring

Robot trajectory programming made easy with the ESCO Paint App

Fully integrated into the ABB GoFa robot controller, the ESCO Paint App enables operators to create coating trajectories intuitively without complex programming or extensive training. Simply guide the robot by hand and start building the trajectory.

Teach your robot to coat parts in just minutes.

Full control over the coating process

With ESCO Paint App, you can configure every aspect of the coating process:

- Define coating parameters

- Set up the work object and trajectory zone

- Configure the coating tool (choose between different angled spray gun adapters)

- Adjust TCP distance from the surface

- Select movement instructions (MoveJ, MoveL)

Programs can be saved and launched in test mode, giving operators instant feedback on how the robot interprets the defined trajectories and commands. This ensures fast deployment straight into production.

Designed for both high-volume and custom production

The ESCO Paint App accelerates production while guaranteeing consistency and repeatability. With optional integration of a 3D optical system, the application can detect the position of hanging parts, automatically recognize their orientation, and adjust the trajectory in real time. This flexibility ensures a stable and sustainable coating process.

Key features of ESCO Paint App

- Two trajectory learning modes:

- Point-to-Point – programming the trajectory by defining individual points

- Continuous Mode – continuous recording of operator-guided robot motion

- Intuitive control via buttons on the robot

- Algorithm for prediction and elimination of robot singularities

- Conveyor tracking support (coating while parts move on a conveyor)

- 3D optical system integration for part detection with automatic trajectory correction

- Storage and testing of robot trajectories outside the coating process

ABB GoFa collaborative robot features

Powerful yet safe

Equipped with advanced torque sensors on all six axes, GoFa provides precise control, power limitation, and force monitoring. The system immediately halts if contact is detected between the robot arm and a human, minimizing the risk of injury.

High performance for high productivity

With TCP speeds of up to 2.2 m/s, GoFa achieves shorter cycle times compared to typical collaborative robots in its class.

- TCP speed up to 2.2 m/s – faster than most cobots in its category

- Reach up to 1.62 m – 14% longer than standard collaborative robots

- Up to 20% energy savings

- Best-in-class repeatable accuracy of 0.02 mm

- Integrated axis design with torque sensors for controlled power and force limitation

- Rounded, impact-safe design that reduces the risk of pinching or trapping injuries

- Certified safety level PL d Cat 3

- Certified for use in explosive environments – Zone 22 (Ex)

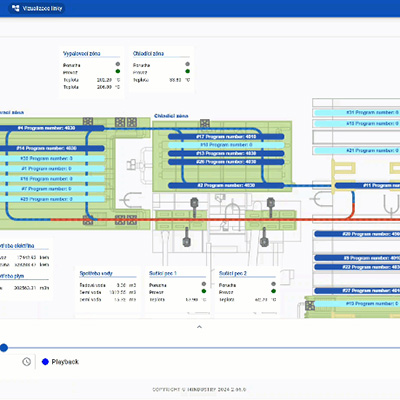

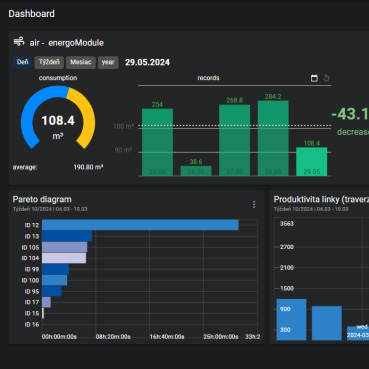

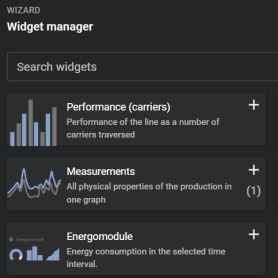

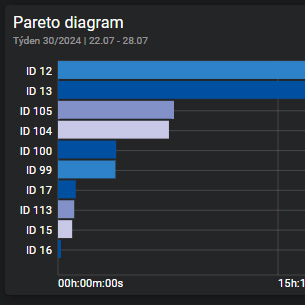

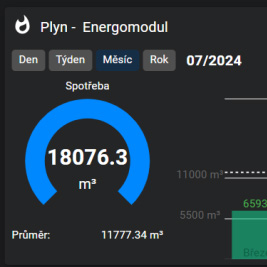

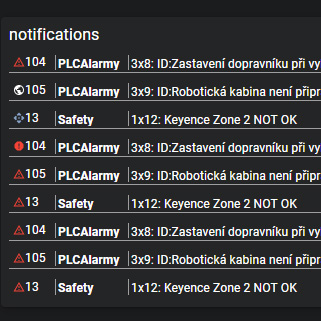

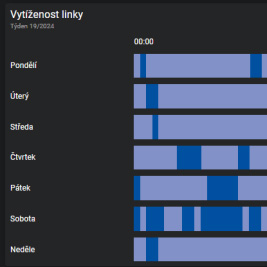

The inSight IIoT platform is an advanced digital platform for optimization and automation of coating lines, helping to improve the quality and productivity of the entire production process. The system offers tools for production control, monitoring and analysis, all in one intuitive environment. Available anytime, anywhere.

Features:

- Complete visualization and management of the coating line from a single source

- Energy monitoring to track and optimize energy consumption

- AlarmsPareto for analysis of the most common alarms and events

- MES module for complete control of the production process through to integration with ERP

- Remote access from any device with a web browser

- Notifications and alarms with filtering and messaging capabilities

- Module for communication with company ERP system (SAP, K2, KARAT, etc.)

- Data export to XLS and CSV formats for further analysis