Powder coating plant for manhole cover manufacturer - Chvaletice

-

Client:KASI Foundry a.s.

-

Year:2019

-

Loacation:Chvaletice (CZ)

-

Technical specification:

- Product dimension limits:

- 1150 × 300 × 1150 mm (L × W × H)

- Product weight limit: 150 kg/m

- Coveyor speed: 3,2 m/ min

- Automatic coating booth for primer application

- 2× CMA paint robot

- Gelling oven

- Automated coating booth for top coat application

- Cleaning booth

- Clean room

- Polymerization oven

- Cooling zone

- Automated conveyor system

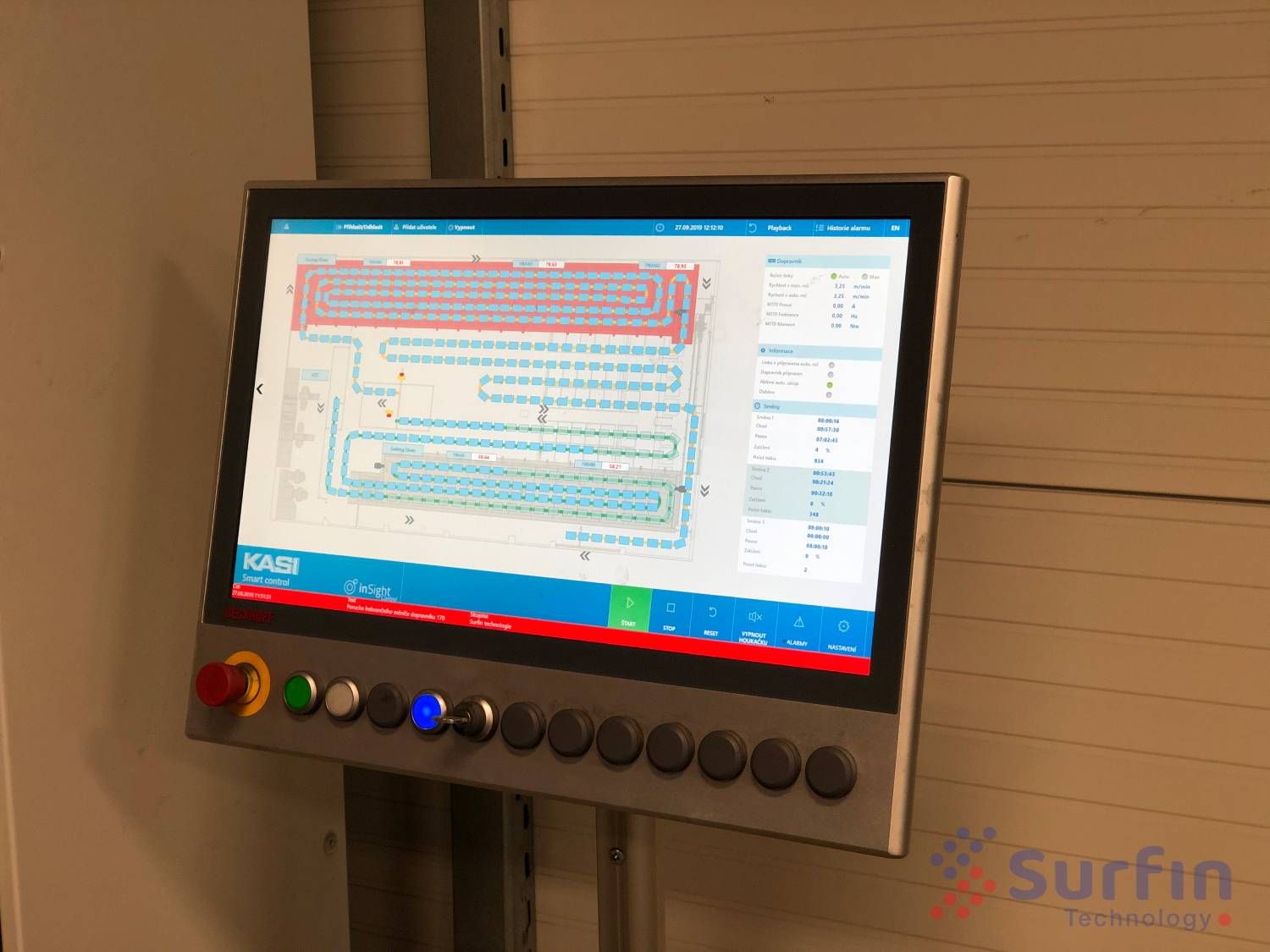

- inSight control system

Project description

Until recently, the only way to give a new coat to cast iron was to apply a layer of wet paint. In SURFIN Technology, we like to discover new paths, and here we managed to find one for Kasi Foundry. Reyclability of oversprayed powder, undisputable assets of robotic painting and the so-called green cure primer polymerization, thick pieces of cast iron products can be treated at lower costs than with solvents. For Kasi, we built a fully automated coating line with two automatic booths and a robotic finishing treatment together with a curing oven and a polymerization oven. Customers satisfaction is proven by the fact that a new powder coating line was installed in Kasi's second plant in Nový Bydžov two years later.